Have you ever found yourself in a situation where you had to choose between a gate valve and a ball valve? Have you ever wondered about the differences between these two types of valves and how they work? If so, you’re not alone. Many professionals in various industries, including the oil and gas, chemical, petrochemical, water and wastewater, and pharmaceutical industries, often face this dilemma.

Gate valves and ball valves are both essential components in many industrial applications.

They are used to control the flow of liquids, gases, and slurries in pipelines. While they serve a similar purpose, their design, operation, and applications are quite different. Understanding these differences is crucial in making the right choice for your specific needs.

So, let’s delve deeper into the world of gate valves and ball valves, and find out which one is the best fit for your requirements.

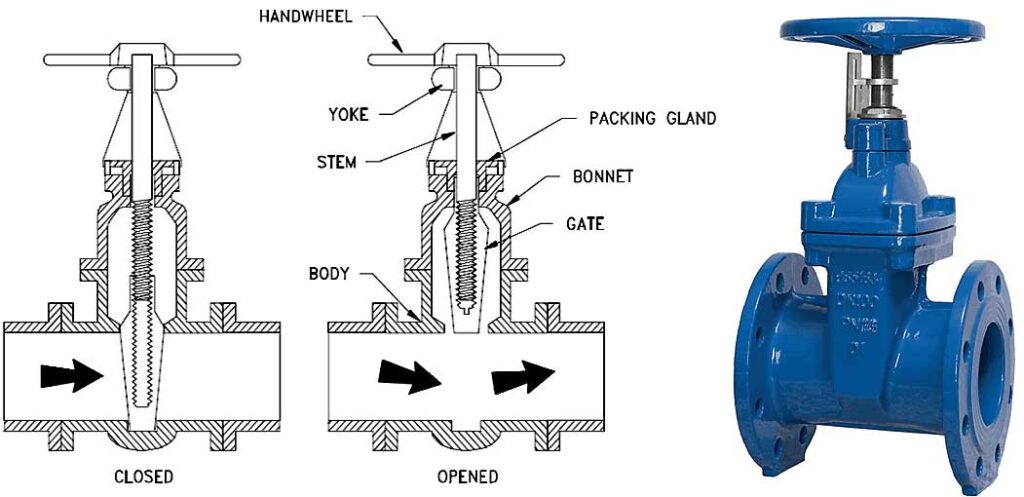

What is a Gate Valve and How Does it Work?

A gate valve, also known as a sluice valve, is a type of valve that uses a gate or wedge to control the flow of fluid. The gate is usually wedge-shaped and is lifted up or down by a threaded stem. When the valve is fully open, the gate is fully drawn up into the valve, allowing for full flow.

Gate valves are designed for fully open or fully closed service. They are installed in pipelines as isolating valves, and they should not be used as control or regulating valves. Due to their ability to cut through liquids, they are often used when a straight-line flow of fluid and minimum flow restriction are needed.

What is a Ball Valve and How Does it Work?

A ball valve, on the other hand, is a valve that uses a spherical disc to control the flow of fluid. The ball has a hole, or port, through the middle so that when the port is in line with both ends of the valve, flow will occur. When the valve is closed, the hole is perpendicular to the ends of the valve, and flow is blocked.

Ball valves are known for their excellent sealing capabilities. They provide tight sealing with low torque and are often used in applications where tight shut-off is required. They are also easy to operate and can maintain and regulate high pressure, high volume, and high temperature flow.

Ball valves come in two main types: full port and reduced port. A full port ball valve has an internal diameter that is identical to the inner diameter of the pipe it’s connected to. This design ensures minimal resistance or drop in pressure as fluids pass through, and it also requires less torque to operate, making it more efficient.

ONE-PIECE BALL VALVE (1PC)-REDUCED BORE

The body is formed from a single body piece in a one-piece ball valve. The ball is permanently fixed within the valve body, and the ends are threaded or welded. One-piece ball valves are compact and cost-effective, commonly used in applications with lower pressure and smaller sizes.

TWO-PIECE BALL VALVE (2PC)-FULL BORE

This type of ball valve consists of two separate pieces connected with thread or bolts. The body is divided into two halves, allowing easy access to the internal components, including the ball and seats. Two-piece ball valves are commonly used in applications requiring regular maintenance or inspection.

THREE-PIECE BALL VALVE (3PC)-FULL BORE

Three-piece ball valves are constructed with three separate pieces: a body and two end caps. The end caps are connected to the body using bolts, allowing easy disassembly and maintenance. This ball valve type offers greater flexibility for repairing or replacing internal components.

Gate Valve vs Ball Valve: Which One Should You Choose?

The choice between a gate valve and a ball valve depends largely on your specific application and needs.

If you require a valve for on/off, non-throttling applications, or when a straight-line flow of fluid and minimum flow restriction are needed, a gate valve might be the right choice for you. They are also a good choice when you need to cut through a heavy liquid or when tight sealing is not required.

On the other hand, if you need a valve that provides tight sealing with low torque, a ball valve might be the best option.

Ball valves are also a great choice for applications that require simple operation and maintain and regulate high pressure, high volume, and high temperature flow.

Conclusion

In conclusion, both gate valves and ball valves play crucial roles in various industrial applications. The choice between the two depends on your specific needs and applications. Always consider the nature of your fluid, the function of the valve, and the conditions under which the valve will operate when making your choice. Remember, the right valve can make a significant difference in the efficiency and safety of your operations.