CHECK VALVES

ALL YOU NEED TO KNOW ABOUT CHECK VALVES

A check valve is a type of valve that allows fluid (liquid or gas) to flow through it in only one direction. Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. They operate automatically, and a person or any external control does not control most; accordingly, most do not have any valve handle or stem.

Alternate Names for Check Valves

Check valves go by different names in various industries. You might hear them called “clack valves,” “non-return valves,” or “one-way valves.” Despite the variety of names, the function remains the same: to prevent reverse flow of fluids.

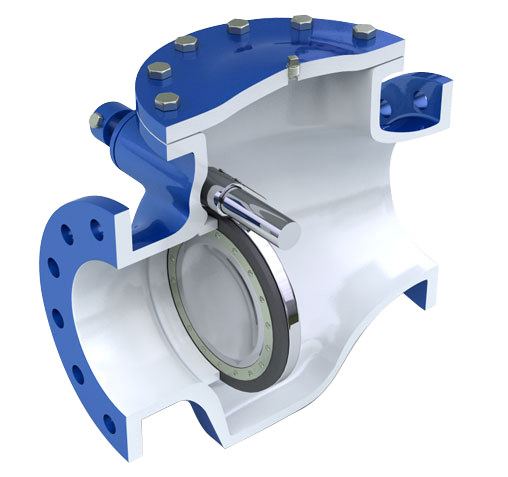

Valve Body

The valve body is the external casing and serves as the framework for all other parts. It usually has two ports: an inlet and an outlet. The body can be made from various materials like brass, plastic, or stainless steel, depending on the application.

Seat

The seat is the part against which the moving element (e.g., a ball or a clapper) seals to stop the flow of fluid. The seat is typically made from materials that can form a tight seal, like rubber or specialized plastics.

Moving Element

This is the part that moves to either open or close the flow path. In a ball check valve, this would be the ball; in a swing check valve, it would be the swinging disk or clapper. This element is typically made of a material compatible with the fluid it will be in contact with.

O-Rings and Gaskets

O-rings and gaskets are used to create a tight seal between the various parts of the valve, preventing leaks. These are typically made from elastomeric materials that can withstand the type of fluid and the operating pressures and temperatures.

Bonnet

Some designs may include a bonnet, which helps encase the moving parts and can be removed for maintenance or part replacement.

Retainer or Guide Pins

In some designs, especially those of ball check valves, retainer or guide pins are used to keep the moving element properly aligned within the body. These pins ensure that the moving element will effectively seal against the seat when the flow reverses.

TYPE BY connection design

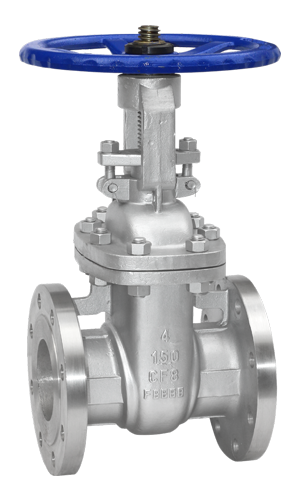

Flanged Gate Valves: These valves have flanges on both ends that are bolted to the piping system. The flanges can be raised face or flat face, and the type of flange used depends on the requirements of the system. Flanged gate valves are easy to install and remove, making them suitable for applications where regular maintenance is required.

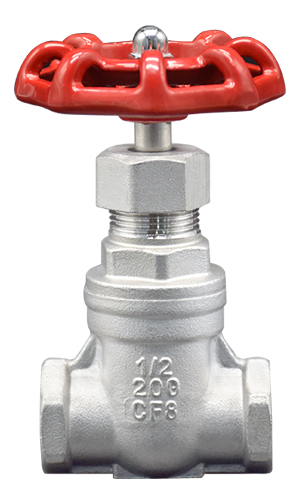

Threaded Gate Valves: These valves have threaded ends that screw directly into the piping system. They are typically used in smaller piping systems and for applications where the pressure is not too high. Threaded gate valves are also known as screwed gate valves.

Welded Gate Valves: These valves are permanently welded into the piping system. There are two types of welded gate valves: butt-weld and socket-weld. Butt-weld gate valves are used in larger piping systems, while socket-weld gate valves are used in smaller piping systems. Welded gate valves are used in applications where a strong, leak-proof connection is required.

TYPE BY stem design

Rising Stem Gate Valves: In a rising stem gate valve, the stem rises as the valve is opened and lowers as the valve is closed. This happens because the stem is threaded and mated with the bushing threads of the yoke. When the handwheel is turned, it drives the stem up or down, moving the gate along with it. This design allows for an immediate visual indication of the valve’s status: if the stem is raised, the valve is open; if the stem is lowered, the valve is closed. Rising stem gate valves are commonly used when it’s important to know by a quick glance whether the valve is open or closed.

Non-Rising Stem Gate Valves: In a non-rising stem gate valve, the stem does not rise or lower. Instead, the gate travels up and down the stem like a nut on a bolt. The stem is threaded on its lower end, and as the handwheel on top is turned, the gate moves up or down the stem on the threads, while the stem itself remains vertically stationary. This design is used where vertical space is limited or underground where the stem would be difficult to see.

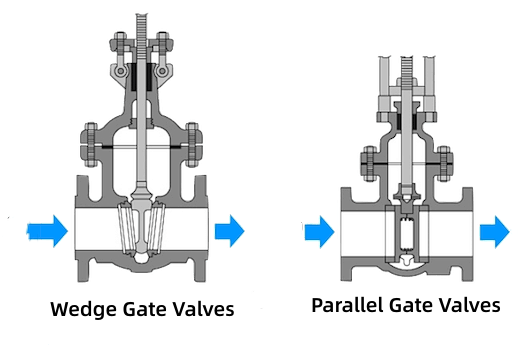

Gate Valve Types By Gate Design

Wedge Gate Valves: These valves have a wedge-shaped gate that fits between two inclined seats. The wedge shape of the gate and the inclined seats allow for a tight seal to be formed when the valve is closed. There are three types of wedge gate valves: solid wedges, flexible wedges, and split wedges. The choice of which to use depends on the specific requirements of the system.

Parallel Gate Valves: These valves have a flat gate between two parallel seats. Parallel gate valves often use a floating gate, which is pushed against the seat by the medium pressure to ensure a tight seal. Some parallel gate valves use two gates with a mechanism to compress the gates against the seats.

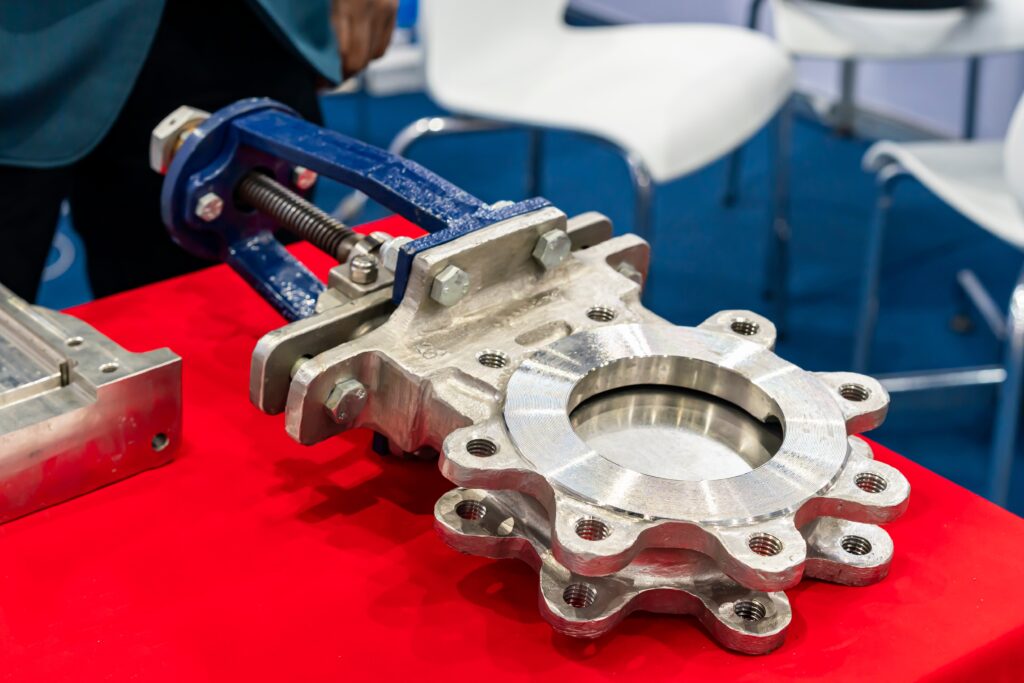

Knife Gate Valves: These valves have a thin, sharp gate that can cut through thick fluids and slurries. Knife gate valves are typically used in applications where the fluid has a high concentration of suspended solids, such as in the pulp and paper industry.

Slab Gate Valves: These valves have a simple, single-piece, rectangular gate that slides between two parallel seats. Slab gate valves are typically used in applications where a straight-line flow and minimum restriction is required, such as in the oil and gas industry.

GATE VALVE Types By Seat Design

Metal-Seated Gate Valves:

These are traditional gate valves where the gate and seats are made of metal. When the gate is closed, metal to metal contact occurs between the gate and the seats. This design is durable and can withstand high temperatures and pressures, but it may not provide a completely leak-proof seal.

Resilient Seated Gate Valves: These valves feature a seat made of resilient material, often rubber, that flexes or deforms slightly to provide a tight seal when the gate is closed. The gate itself is usually made of metal, and when it comes into contact with the resilient seat, the seat deforms to accommodate the gate and form a seal. This design allows for a very tight seal that can effectively prevent leaks, even at low pressure differentials.

Gate Valve Types By Bonnet Design

Bolted-Bonnet Gate Valves: This is the most common design where the bonnet is bolted to the valve body. This design allows for easy maintenance and repair as the bonnet can be removed to access the internal parts of the valve.

Screwed Bonnet Gate Valves: This design features a bonnet that is screwed into the valve body. It’s a simple and compact design often used for smaller, low-pressure valves.

Pressure-Seal Bonnet Gate Valves: These valves are designed for high-pressure applications. The bonnet is sealed to the valve body by the pressure of the fluid in the valve. As the pressure increases, the seal becomes tighter. This design is suitable for high-pressure applications but can be more difficult to maintain and repair.

Union Bonnet Gate Valves: In this design, the bonnet is connected to the body of the valve with a threaded union. This allows for easy removal of the bonnet for maintenance and inspection.

GATE VALVE VS BALL VALVE

While both ball valves and gate valves fall under the category of on/off valves, their designs differ in several ways.

Ball valves operate by rotating a ball, which has a hole drilled through its center, by a quarter turn to allow the flow of media. Conversely, gate valves function by vertically lifting or lowering a gate mechanism through the rotation of a handwheel.

Due to the design of the gate mechanism, gate valves typically have a lower likelihood of leakage compared to ball valves.

Closed Position: When the gate valve is in the closed position, the ‘gate’ or ‘disc’ is dropped into the path of the fluid flow. This gate is typically wedge-shaped and fits snugly into a matching seat, effectively blocking the flow of fluid.

Opening the Valve: To open the valve, the operator turns the handwheel in a counter-clockwise direction. This action engages the stem, which is connected to the gate. As the stem is threaded, turning the handwheel causes the stem (and the attached gate) to rise.

Open Position: As the handwheel is turned, the gate moves up and away from the fluid path. When the gate valve is fully open, the gate is completely clear of the fluid path, allowing fluid to flow freely through the valve with minimal pressure drop.

Closing the Valve: To close the valve, the operator turns the handwheel in a clockwise direction. This causes the stem (and the attached gate) to lower back into the path of the fluid, blocking flow.

Regulating Flow: Although gate valves are typically used in either a fully open or fully closed position, they can be partially opened to regulate flow. However, this is not typically recommended as it can cause wear and tear on the valve, potentially leading to a reduced lifespan.

How gate valve works?

What aspects should be considered when purchasing a gate valve?

Type of Fluid: Different gate valves are suitable for different types of fluids. For example, certain materials used in the construction of the valve may be more resistant to corrosive fluids, while others may be suitable for handling high-temperature fluids.

Pressure and Temperature: The pressure and temperature that the valve will be subjected to are also important considerations. Some gate valves are designed to withstand high pressures and temperatures, while others are designed for lower pressure and temperature applications.

Valve Size: The size of the valve should match the size of the pipe in which it will be installed.

Operation: Consider how the valve will be operated. Some gate valves are manually operated using a handwheel, while others may be operated using an electric, pneumatic, or hydraulic actuator.

Sealing Requirements: If a tight seal is required when the valve is closed, you may want to consider a gate valve with a resilient seat.

Material: The material of the valve should be chosen based on the application. For example, stainless steel might be chosen for its corrosion resistance, while cast iron might be chosen for its durability and cost-effectiveness.

Standards and Certifications: The valve should meet any relevant industry standards and certifications, especially if it will be used in critical applications.

Maintenance: Consider the ease of maintenance. Some designs are easier to maintain than others.

Cost: Finally, the cost of the valve is always a consideration. It’s important to balance cost with the other factors to ensure you are getting a valve that will meet your needs and provide reliable service.

HELP YOU SELECT THE RIGHT VALVES

Send us a message if you have any questions about gate valves. Our experts will give you a reply with 24 hours to help you select the right valve you want.

Tel: +86-577-88893652

Email: [email protected]

ALL YOU NEED TO KNOW ABOUT CHECK VALVES

A check valve is a type of valve that allows fluid (liquid or gas) to flow through it in only one direction. Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. They operate automatically, and a person or any external control does not control most; accordingly, most do not have any valve handle or stem.

Add Your Heading Text Here

Drop

A more powerful pump is not necessary for the movement of fluid and gas. This implies that there's a minimal pressure transition from high to low, which assures the seamless operation of the pipe components.

Stem

The valve design doesn't incorporate a stem component that shifts up or down with motion. As a result, no fluid or gas escapes the pipeline when the valve is activated or deactivated.

Drop

A more powerful pump is not necessary for the movement of fluid and gas. This implies that there's a minimal pressure transition from high to low, which assures the seamless operation of the pipe components.

Stem

The valve design doesn't incorporate a stem component that shifts up or down with motion. As a result, no fluid or gas escapes the pipeline when the valve is activated or deactivated.

HOW BALL VALVE WORK?

Ball valves work by utilizing a rotating sphere (or “ball”) with a hole bored through the center. Here is a simple explanation of how a ball valve works:

Open Position: When the valve is in the open position, the hole in the ball is aligned with the direction of the flow path, meaning that fluid can flow through it. The handle of the valve is usually in line with the hole in this position.

Closed Position: When the valve is closed, the ball is rotated 90 degrees so that the hole is perpendicular to the flow path, meaning fluid cannot pass through. The handle is typically perpendicular to the hole in this position.

Where Are Ball Valves application

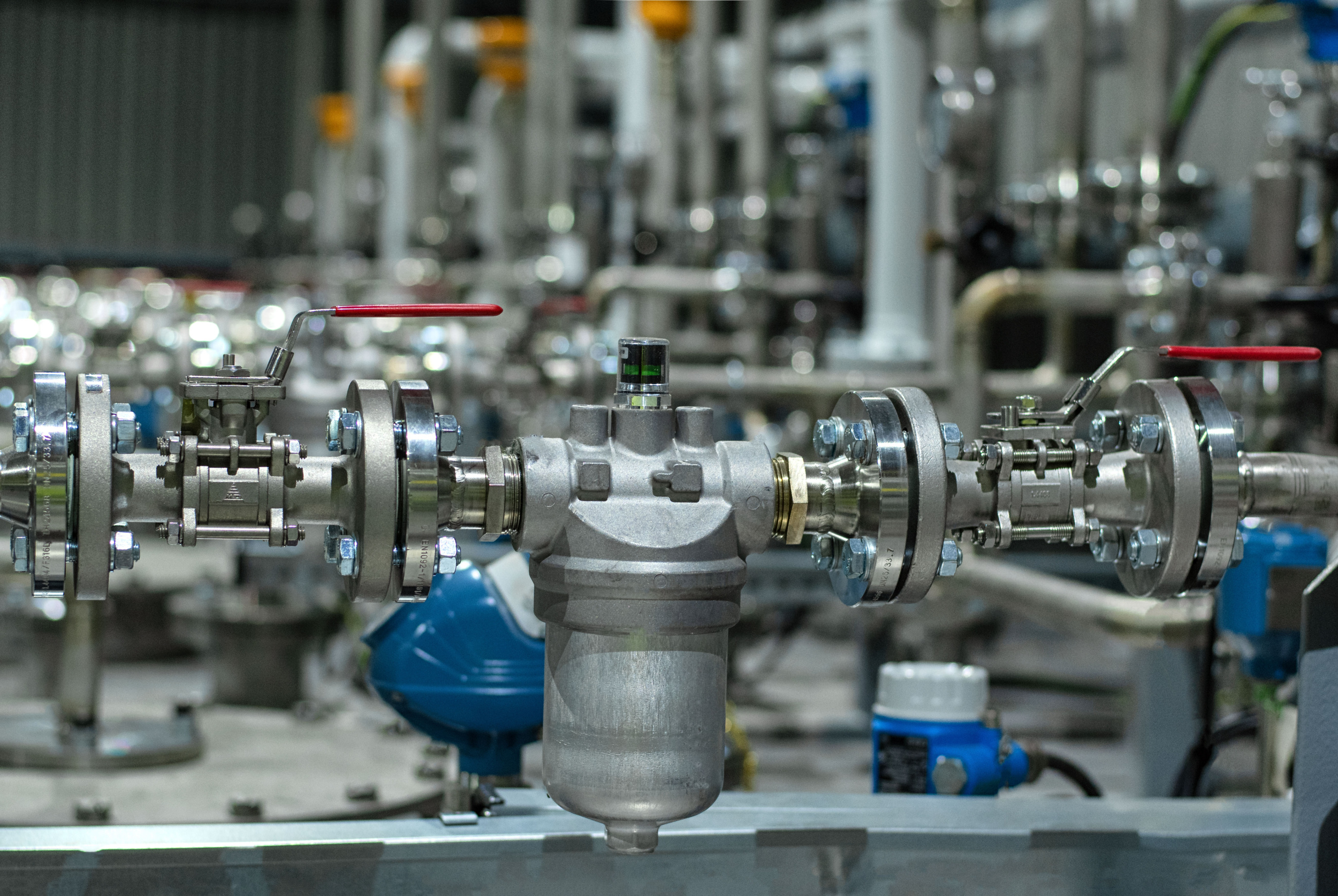

Ball valves are used in a wide variety of applications across many industries due to their reliability, durability, and ease of operation. Here are some common applications:

- Oil and Gas Industry: Ball valves are used for controlling the flow of oil and gas in pipelines and other processing equipment.

- Chemical Industry: They are used in chemical plants for controlling the flow of various chemicals in the processing lines.

Water and Wastewater Treatment: Ball valves are used in water supply systems and wastewater treatment plants for controlling the flow of water and other fluids.

Food and Beverage Industry: They are used in food processing and beverage production lines to control the flow of liquids and semi-liquids.

Pharmaceutical Industry: Ball valves are used in pharmaceutical manufacturing for controlling the flow of ingredients and finished products.

Power Generation: In power plants, ball valves are used in various systems such as cooling, lubrication, and fuel supply.

7. Marine Applications: Ball valves are used in various marine applications, including fuel systems, water systems, and waste systems on ships.

8. Residential Plumbing: In homes, ball valves are commonly used as shut-off valves in water supply lines.

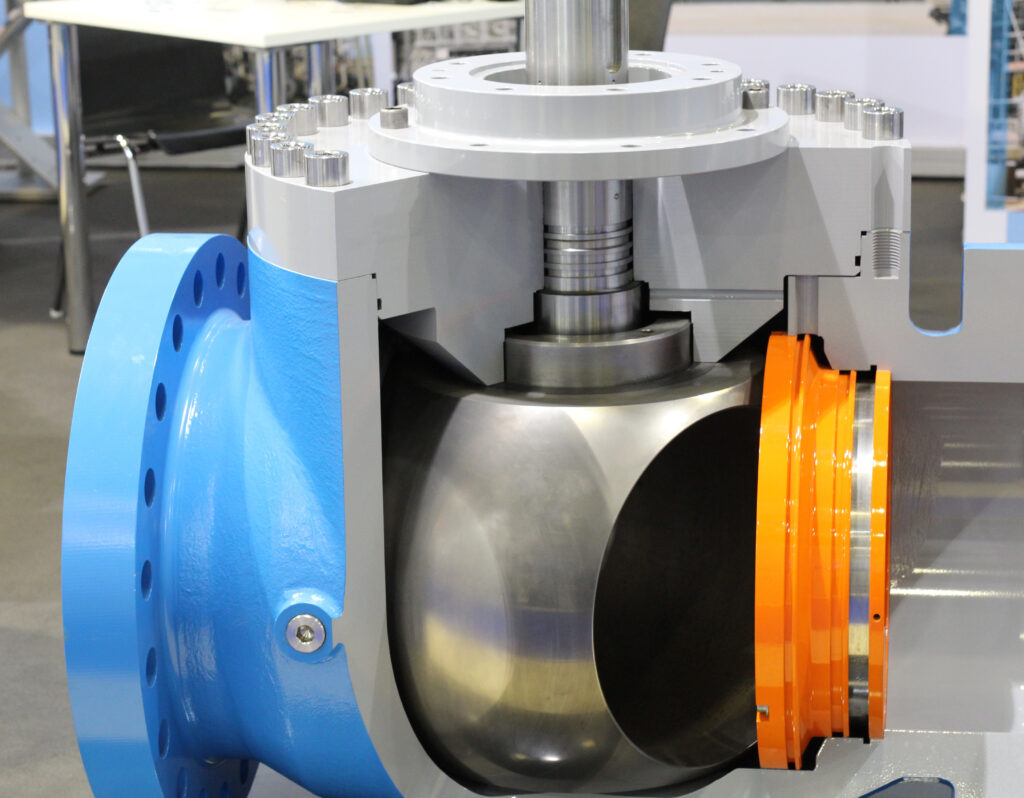

Body

The body of the valve, made from stainless steel, is the outer casing and provides the main structure. It contains the internal parts and has connections (ports) for the pipeline.

Ball

The ball is the central component that controls the flow of fluid. It's a sphere with a hole through the middle, which aligns with the pipeline when the valve is open and is perpendicular to it when the valve is closed.

Stem

The stem is the part that connects the handle to the ball. When the handle is turned, the stem rotates the ball.

Seats

The seats are rings of softer material (often PTFE or another plastic) that form a seal between the ball and the body when the valve is closed. There are typically two seats, one on either side of the ball.

Seals

Seals or packing material are used to prevent leakage along the stem. They ensure that when the valve is closed, no fluid can escape.

Bonnet

The bonnet is a part of the valve body that holds the stem. It's often bolted onto the body and provides a seal to prevent leaks.

FACTORS TO CONSIDE WHEN CHOOSE BALL VALVE

1# Material

The material of the valve should be compatible with the fluid or gas it will control. Common materials include stainless steel, brass, and plastic, each suitable for different applications.

2# Type of fluid

The type of fluid that the valve will control is crucial. Different materials are suitable for different types of fluids, and the valve must be compatible with the fluid to prevent corrosion or damage.

3# pressure rating

The pressure rating of the valve should be suitable for the application. If the pressure is too high for the valve, it could fail.

4# size

The size of the valve should match the size of the pipe it will be connected to.

5# TEMPERATURE

The temperature of the fluid can also affect the performance of the valve. Some materials can withstand high temperatures, while others cannot.

7# Operation

Consider whether you need a manual or automated valve. Manual valves are operated by hand, while automated valves can be controlled remotely or programmed to open and close at certain times.

6# Seat & Packing Material

Ball valve seats are made from different materials depending on the application. Soft seats, often made from PTFE (like Teflon), are great for sealing but have limited pressure thresholds, making them suitable for low-pressure applications. Filled PTFE is used for mid-range pressure applications, while high-pressure applications use PEEK. Neoprene or fluorocarbon elastomer is used for applications resistant to oil and moderate chemicals but not for highly corrosive acids. For high-temperature applications, graphite is used due to its heat resistance. The choice of seat material depends on the pressure rating of the ball valve and the materials it will be in contact with.

8# Port

Ports, serving as the inlet and outlet points of valves, can be either full or standard. They have the ability to limit the flow of fluids or gases.

- Full Bore Ball Valve

A full bore ball valve is a valve with a hole, or port, that matches the pipe’s inside diameter. This design allows unrestricted fluid flow, minimizing pressure loss.

- Reduced Ball Valve

A reduced bore ball valve has a port smaller than the pipe’s diameter, causing some restriction to fluid flow and a potential pressure drop. They are typically smaller, lighter, and less costly than full bore valves, suitable for non-critical flow rate applications.

- V -Port Ball Valve

A V-port ball valve has a V-shaped hole in the ball, allowing precise control over flow rate. It’s ideal for applications requiring flow modulation, providing a wide range of control over the fluid or gas passing through.

HELP YOU SELECT THE RIGHT VALVES

Send us a message if you have any questions about ball valves. Our experts will give you a reply with 24 hours to help you select the right valve you want.

Tel: +86-577-88893652

Email: [email protected]